-40%

mobarel - Aviation tin Snips - Long Style, Off-Set Cut, & Right / Left Cut

$ 9.49

- Description

- Size Guide

Description

Products Description1.Special Laborsaving Design

Designed for easier cutting Meets ANSI and DIN standard.

2.Center Fastener

High tensile strength provided for longer life.

3.Double Overwind Spring

High torsional strength spring designed for longer life.

4.Comfortable Grips

Solid and comfortable handle with non- slip design.

5.Serrated Edges

Stable bite prevents slipping.

6.Hot Drop-Forged Blades

Chrome-Molybdenum Alloy steel forged blades for greater strength and longer durability.

7.Hang Hole

Hang up hole provided for convenient storage.

8.Safety Auto Latch (D, PAT.)

New quick and simple spring-free automatic latch

design (one hand release) provides safety and convenience.

Aviation Snips Introduction

Snips are made in various shapes and sizes for various tasks. The handle can be like those on scissors with finger and thumb holes or like plier handles. Models are available for cutting in straight lines, in curves to the left or curves to the right.

Universal snips can cut in both straight and wide curves.

Straight snips and duckbill snips (flat blade, "perpendicular" to the handle, with pointed tips) are designed to cut in straight lines; some duckbill snips are designed for cutting curved lines.

Hawk's bill snips (with crescent-shaped jaws) are used for cutting tight circles.

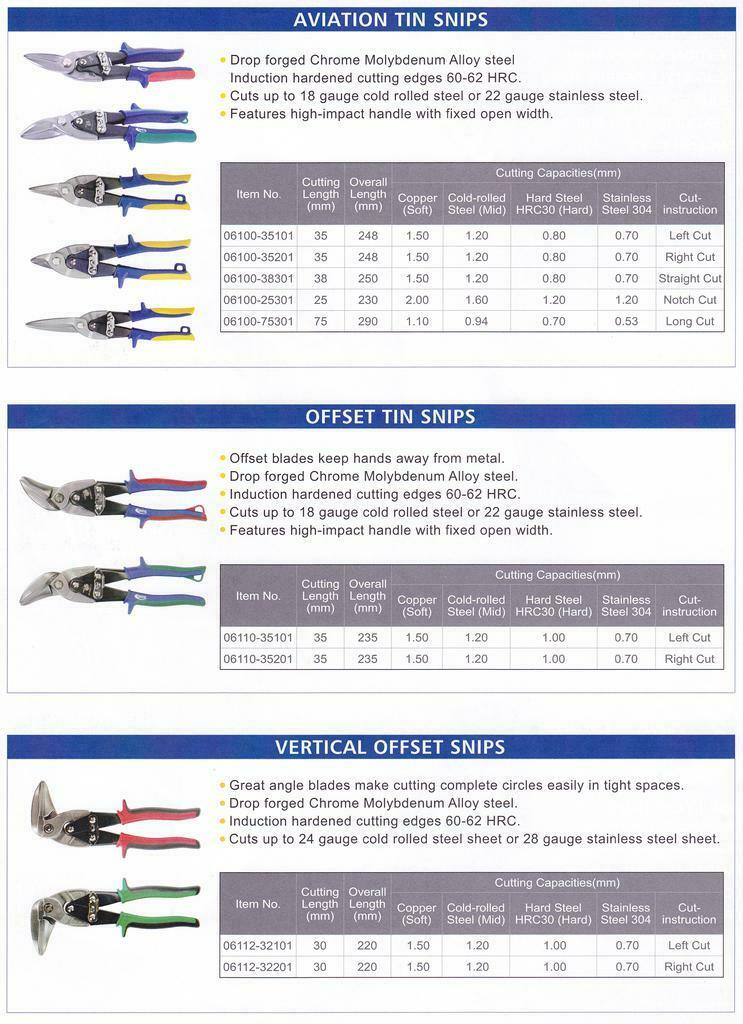

Aviation snips have compound leverage that reduces the effort required for cutting.

Offset snips have jaws that are set at an angle from the handle.

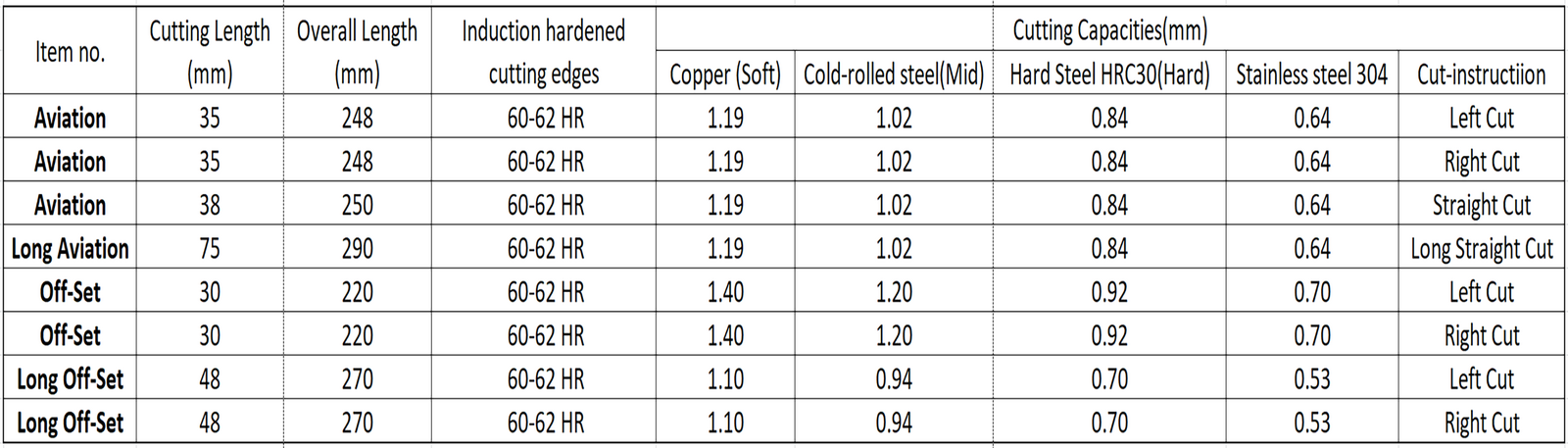

Select the right size and type of snips for the job; check the manufacturer's specifications about the intended use of the snips (e.g., type of cut - straight, wide curve, tight curve, right or left, and maximum thickness and kind of metal or other material that can be cut).

Only use snips that are sharp and in good condition.

Wear safety glasses or goggles, or a face shield (with safety glases or goggles) and protective gloves when working with snips. Small pieces of metal may go flying in the air and the cut edges of metal are sharp.

Left cut snips

are for making cuts to the left and straight cuts.

Right cut snips

are for making straight cuts and cuts to the right.

Straight cut snips

(not shown) are for making straight cuts and shallow cuts to the right or left.

Offset snips

permit you to keep your hands safely above the cut while cutting directly through the centre of a large sheet.

Use snips for cutting soft metal only. Hard or hardened metal should be cut with cutting tools designed for that purpose.

Use ordinary hand pressure for cutting. If extra force is needed, use a larger tool.

Cut so that the waste is on the right if you are right-handed or on the left if you are left-handed.

Avoid springing the blades. This results from trying to cut metal that is too thick or heavy for the snips you are using.

Keep the nut and the pivot bolt properly adjusted at all times.

Oil the pivot bolt on the snips occasionally.

Use the locking clip (if available) to keep the snips closed when not in use.

Do not try to cut sharp curves with straight cut snips.

Do not cut sheet metal thicker than the manufacturer's recommended upper limit (e.g., cuts up to 16 gauge cold rolled steel or 18 gauge stainless steel).

Do not extend the length of handles to gain

greater leverage.

Do not hammer or use your foot to exert extra pressure on the cutting edges.

Do not use cushion grip handles for tasks requiring insulated handles. They are for comfort primarily and not for protection against electric shocks.

Do not attempt to

reshape

snips in a sharpening device designed for scissors, garden tools or cutlery.